Recipe Prediction by Color Gamut

Investigation of the Possibilities of Reuse of Fiber / Coil Dyeing Wastewater Containing Dyestuffs and Auxiliaries without Treatment, Establishment of Recipe Prediction Models According to Color Gamut

Environmentally Friendly Fabrics

Eco-Friendly Fabrics (Extinct or Developed with Natural UN)

CO2 gas utilization in Waste Water Treatment Plants

Development of Ecological Production Methods by Utilizing CO2 Gas in Waste Water Treatment Plants (for pH Balance)

Indigo Decolorization

Separation of Dyestuffs in Indigo Dyed Waters from Denim Mills and Development of Reuse Possibilities of Decolorized Waters

Utilization of Textile Wastewater for SO2 Treatment

Wastewater Neutralization with CO2 in Flue Gas and Use of Textile Wastewater for SO2 Treatment in Flue Gas

100% Recycled Cotton

Development of 100% Recycled Yarn by Rotor, Siro Spun Spinning Methods Using Pre-Consumer Cotton Fiber Wastes

Fabric Dyeing Machinery Water Recycling in Trails

Fabric Dyeing Machinery Water Recycling in Trails

Recycling of Textile Wastes (Chiffonez Plant)

Recycling of Textile Wastes (Chiffonez Plant)

New Cotton

Demonstration And Launch Of High Performance, Biodegradable, Regenerated New Cotton Textiles To Consumer Markets Through An İnnovative, Circular Supply Chain Using Infinited Fiber Technology

Technical Fiber Recycling

Recycling of Technical Fibers and Development of Sustainable Textile Structures

Biodegradable

Production of Biobased or Biodegradable Blended Yarns and Investigation of Their Utilization Performance

European Space Agency

Development of Functional Textile Structures for the European Space Agency

500,000 Neutralization of 361,500,000 kg CO2 through tree planting

500,000 Neutralization of 361,500,000 kg CO2 through tree planting

Rpet Fiber Production Plant

A typical RPET (Recycled Polyethylene Terephthalate) fiber production plant is a facility that specializes in the manufacturing of polyester fibers derived from recycled plastic bottles.

Sapling Plant Project

Thanks to our project, which aims to bring 100 thousand saplings to the soil every year in Kahramanmaraş, we will leave both nature and green space for future generations.

Efficient Steam Boiler Commissioning

A 30% more efficient boiler system was commissioned and CO2 emissions were measured online in the flue gas treatment system with fully automatic combustion efficiency control. Inefficient boilers with old technology (65%) installed for the steam and hot water needed by the dyeing and finishing plants were replaced with high efficiency (95%) fully automated boilers with online measurement control of flue gas, aiming to use less coal per unit steam.

KİPAŞ Paper Waste Incineration Facility with Biomass

Coal consumption has been reduced by burning alternative wastes according to the following scenarios.

In this way, the same energy was provided with 58% less coal usage. Currently, it has been in the process of commissioning biomass combustion boilers in Batı Kipaş for 2 years and in Center Paper Enterprise.

Completely eliminate the use of coal in the high-temperature hot oil boiler used in the drying, pre-fixation

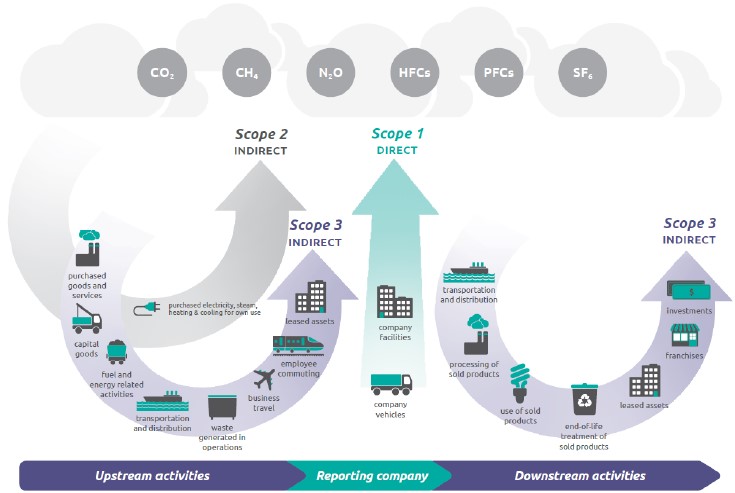

Corporate Carbon Footprint Reporting Project

Transition to 100% Natural Gas Steam Boiler Project

Transition to 100% Natural Gas Steam Boiler Project